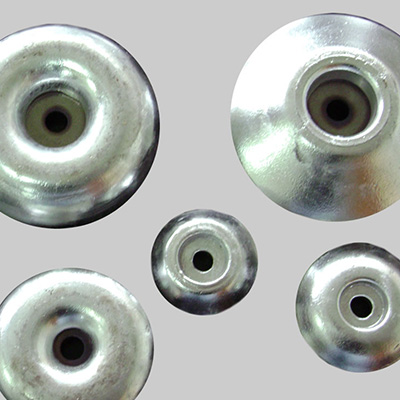

Products

Corrosion is the loss of its metallic properties by entering into a chemical or electrochemical reaction with the environment it is in. In practice; used for cathodic protection of metal structuresin salt water such as offshore platforms, ship hulls, in-tank, underwater pipesand piers.

Pipe internal corrosive waters and waste transportation in the pipe for the transportation of waste and corrosive waters

– Heat Exchanger and Condenser Anodes

– Balancing tanks of ships and oil carriers

– Filled type to discharge leakage current

– Protection of Scaffolding Steel feet

– In the protection of the outer surfaces of the ships

– In special structures

A potential difference of approximately 250mV occurs between the iron metal protected by pure zinc anodes. This difference is sufficient for cathodic protection.

However, if there is even a little iron in the zinc anodes, this potential difference will decrease in a short time. Like iron, the small amount of lead and copper in the zinc anode has a harmful effect.

On the other hand, the presence of aluminum and cadmium metals in the zinc anode helps the anode to produce current properly.

| ELEMENT | ALLOY % |

| Al | 0,10-0,50 |

| Cd | 0,025-0,15 |

| Fe Max | 0,005 |

| Pb Max | 0,006 |

| Cu Max | 0,005 |

| Zn | REMAINING |

| ELECTRO CHEMICAL PERFORMANCE | TEORİK |

| Density (g/cm3) | 7,1 |

| Mass Loss (kg/A.yıl) | 11,5 |

| Mass Yield % max | 90 |

| Akım Kapasitesi (A.h/kg) | 820 |

| Circuit Potential Against Steel mV | 250 |

| Electrode Potential (Cu/CuSO4 Reference Electrode.) mV | 1100 |